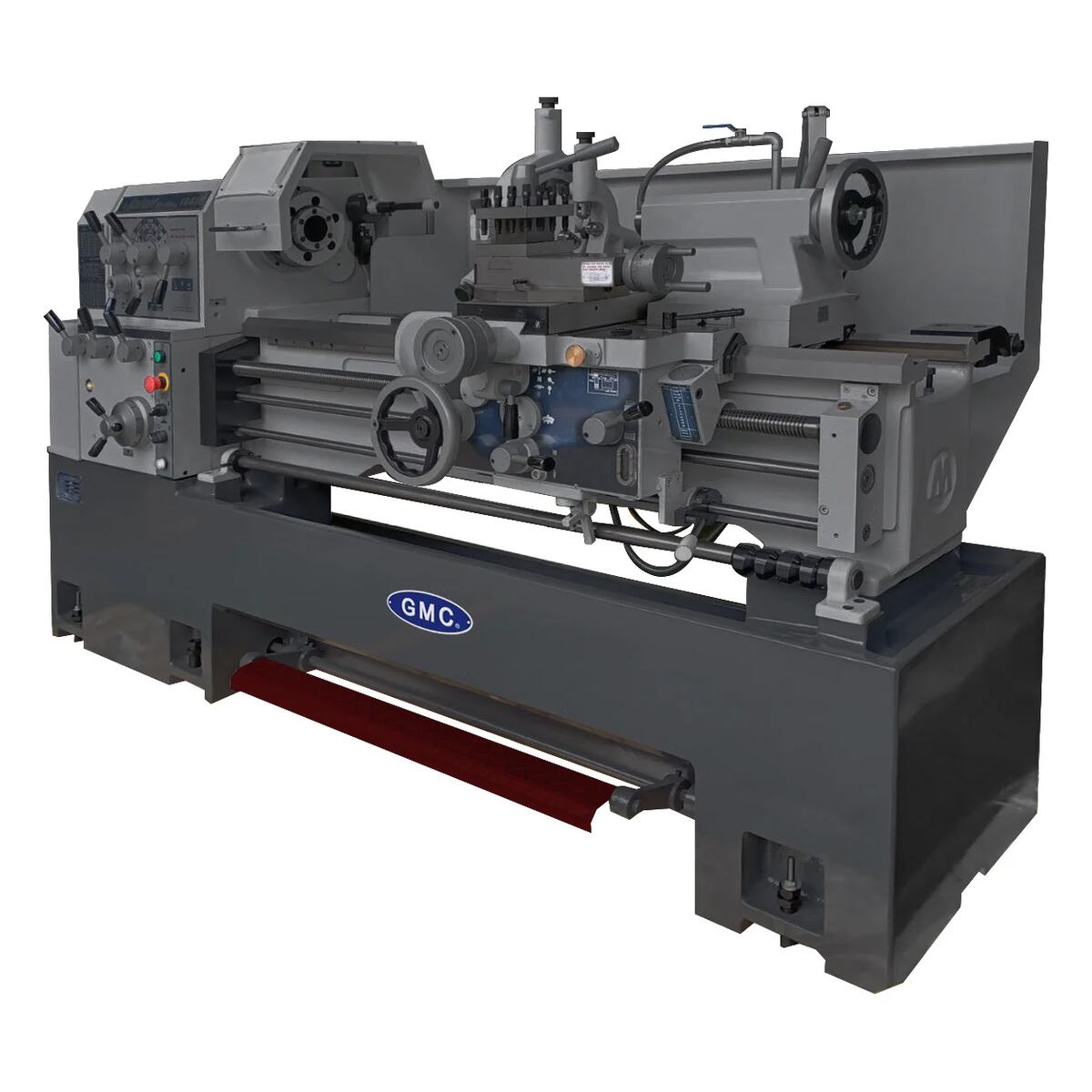

GMC 21” x 60” Heavy Duty Precision Gap Bed Lathes GML-2160T

These models are not currently in stock. Call in to check on lead times! Thank you!

GML-2160T, 21” x 60”, 3-1/8” bore - With free CARMAR DRO installed

- Made in Taiwan

- Meehanite casting – high performance cast iron

- ISO 9001 certified

- Large spindle bore 3-1/8”

- Heavy Duty spindle D1-8

- Heavy Duty guideway width 12”

- Spindle speeds from 40-2,000 rpm, 12 speeds

- Threading and feeding rate change without changing gears

- Spindle is balanced, hardened and precision ground

- Spindle is supported at 3-point by high precision bearings

- All gears and shafts are hardened and precision ground

- Guideways induction hardened and precision ground

- Automatic lubrication system in headstock and feed box

- One year industrial warranty for parts

DISCLAIMER

Please note this machine is incompatible with the use of a rotary phase converter. Any attempt to purchase, install, or employ one, whether carried out by you or a professional service company, will automatically void the warranty. It is crucial to understand that any such actions are entirely the responsibility of the buyer.

This disclaimer is intended to clearly convey that the utilization of a rotary phase converter to power or operate this machine is not supported.

Specifications and Manual

| Specification | GML‑2160T | GML‑2190T |

|---|---|---|

| Capacities & Sizes | ||

| Max. Swing Over Bed | 20‑1/2″ | 20‑1/2″ |

| Max. Length of Workpiece | 60″ | 90″ |

| Max. Swing Over Cross Slide | 13″ | 13″ |

| Max. Swing in Gap | 29‑1/8″ | 29‑1/8″ |

| Bed & Gap | ||

| Width of Bed | 12″ | |

| Effective Length in Gap to Spindle | 6″ | |

| Effective Length in Gap to Chuck Jaws | 3‑1/2″ | |

| Spindle | ||

| Spindle Bore | 3‑1/8″, D1‑8 | |

| Taper of Spindle Center | M.T. #6 w/ reducing sleeve MT6/MT5 | |

| Spindle Speeds | 40–2,000 rpm / 12 steps | |

| Feeds & Threads | ||

| Longitudinal Feeds | 0.002–0.03 IPR, 35 kinds | |

| Cross Feeds | 0.0008–0.011 IPR, 35 kinds | |

| Inch Threads | 4–56 TPI, 36 kinds | |

| Metric Threads | 0.5–7.0 mm, 17 kinds | |

| Slides & Tailstock | ||

| Max. Travel of Top Slide | 5″ | |

| Max. Travel of Cross Slide | 11″ | |

| Spindle Length w/o Chuck | 17″ | |

| Leadscrew Length × TPI | 1‑1/4″ × 4 TPI | |

| Diameter of Tailstock Quill | 2‑3/4″ | |

| Max. Travel of Tailstock Quill | 5‑7/8″ | |

| Taper of Tailstock Quill Center | M.T. #4 | |

| Power & Fluids | ||

| Main Motor | 7‑1/2 HP, 220 V / 440 V, 3‑Ph | |

| Amperage Draw | 35 A (220 V), 20 A (440 V) | |

| Coolant Pump Motor | 1/8 HP, 220 V / 440 V, 3‑Ph, 2 Gal coolant | |

| Machine Oil | # 30 weight, 5 Gallons | |

| Weight | ||

| Machine Weight (approx.) | 4,150 lbs | 5,150 lbs |

| Dimensions (L × W × H) | ||

| Overall Dimensions | 105″ × 41″ × 59″ | 139″ × 41″ × 59″ |

| Shipping Dimensions | 110″ × 38″ × 66″ | 140″ × 38″ × 66″ |

Standard Equipment

- Free CARMAR DRO, installed

- Automatic kick-out longitudinal carriage stop system

- 10” 3-jaw chuck with top reversible jaws, direct mount

- 16” Face plate

- 9” steady rest with roller jaws

- 4” follow rest with roller jaws

- Removeable gap

- 4-way tools post

- Foot brake

- LED Work light

- coolant system

- full length rear splash guard

- Dead centers

- Thread chasing dial

- Reducing sleeve MT6/MT5 for spindle

- Tool box and leveling pads

Optional Add-Ons

- Taper attachment, installed

- 5-C Hand lever type collet closer, free install

- 33 pc 5C collet set, from 1/16”–1-1/16” by 32nd, Part# 3900-0014

- ALORIS type QC tool post set # 3900-5260, 6 pcs

- Live Center # 3900-5004 for tailstock

- Live Center # 3900-5005 for headstock

- Chuck guard