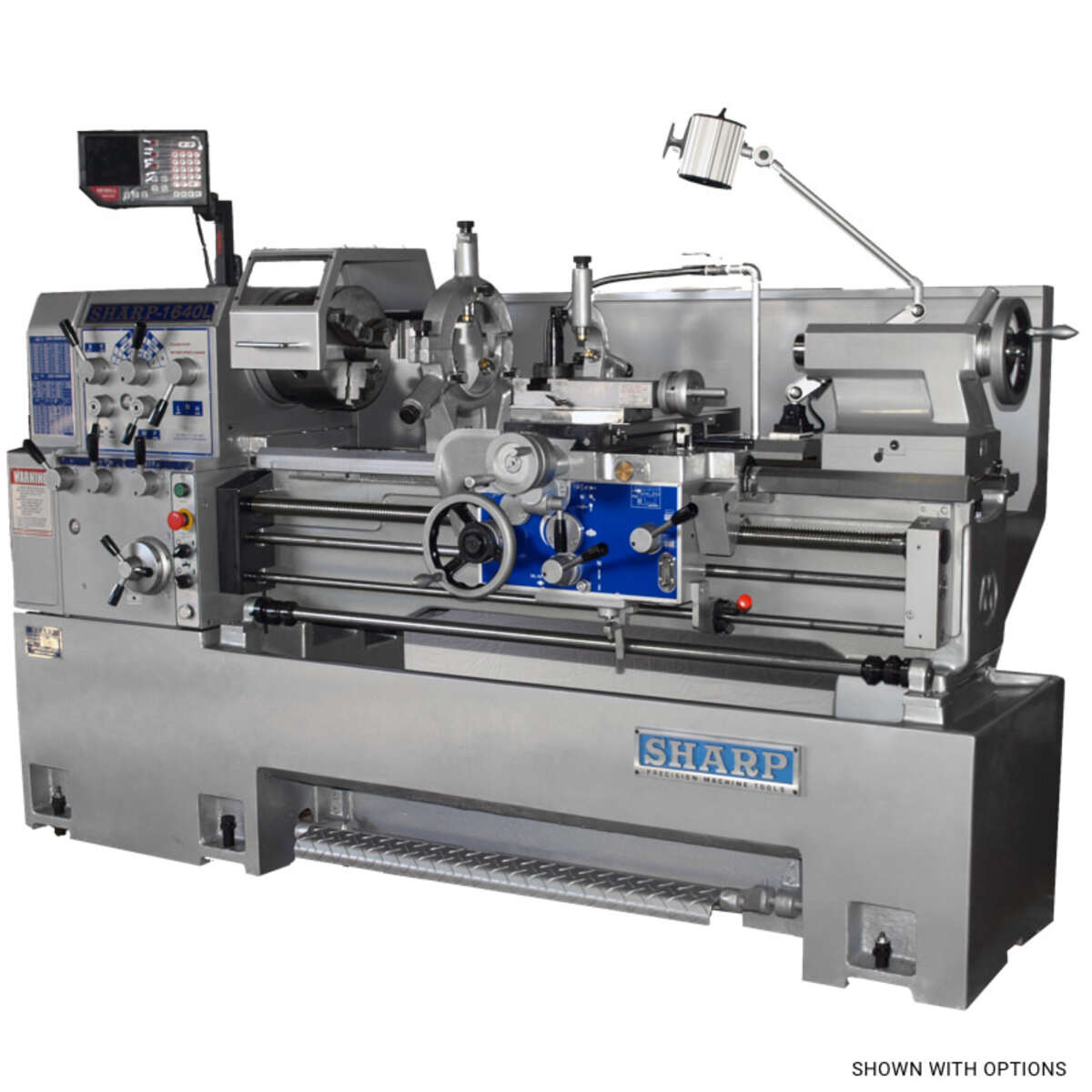

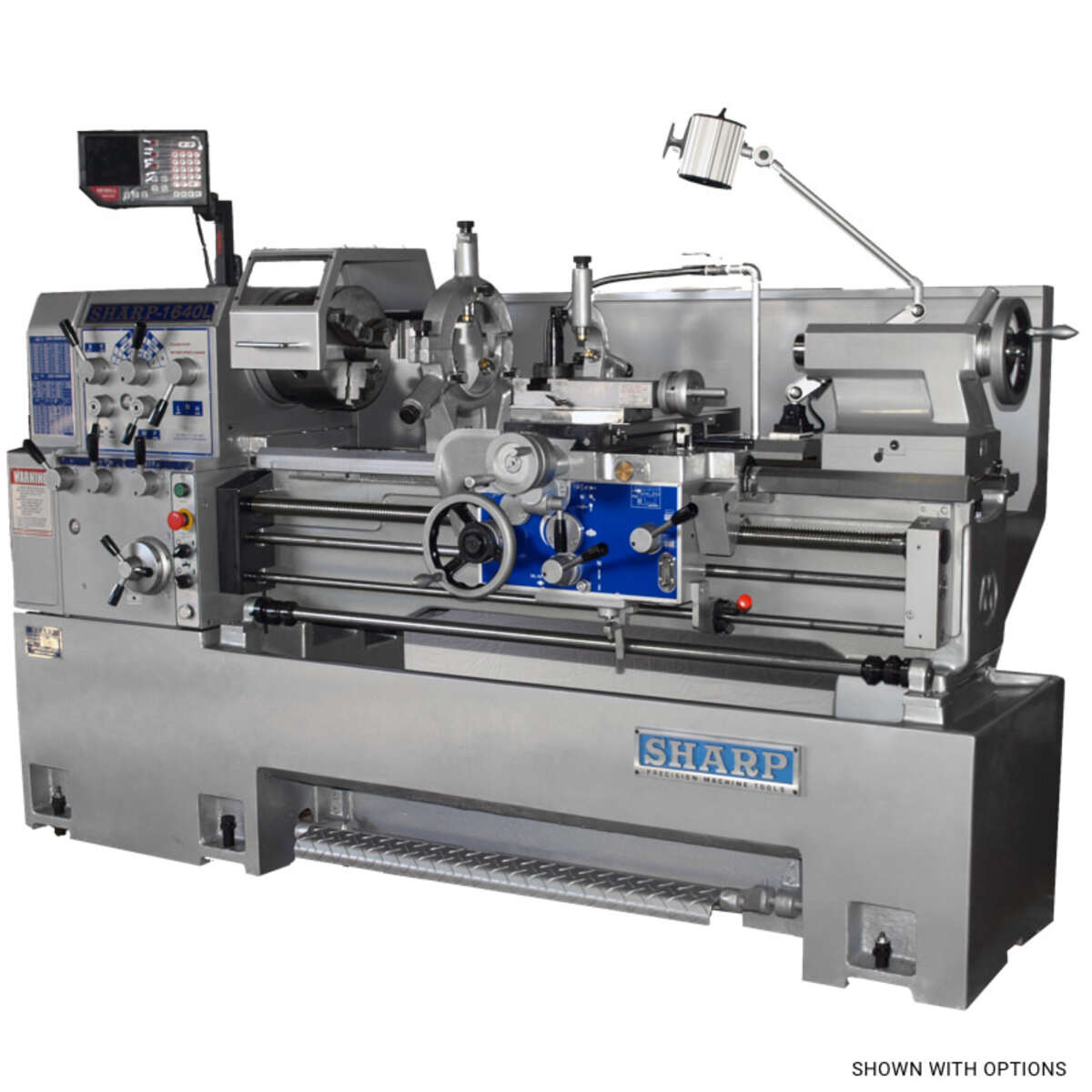

Sharp Industries 18" x 80" Precision Lathe, Geared Head, 7.5HP 1880-L

There is a 6% surcharge on all Sharp products due to tariffs.

Feel free to call in to ensure product availability and lead times.

There is a 6% surcharge on all Sharp products due to tariffs.

Feel free to call in to ensure product availability and lead times.

This model is designed with 3.18” spindle hole which is unique for 18” swing lathes. Due to its one piece casting machine base, it can support heavier cutting on large diameter materials. The large through hole allows most 3” diameter oil pipes to be machined.

| Specification | Inch | Metric |

|---|---|---|

| Capacity | ||

| Swing Over Bed | 18 in. | 457 mm |

| Swing Over Cross Slide | 10.2 in. | 259.08 mm |

| Swing Over Gap | 27.17 in. | 690 mm |

| Gap Width (In Front Of Faceplate) | 11.81 in. | 300 mm |

| Distance Between Centers | 86.6 in. | 2200 mm |

| Headstock | ||

| Spindle Speed | 40–2,000 rpm | 40–2,000 rpm |

| Spindle Nose | D1‑8 camlock | D1‑8 camlock |

| Spindle Bore | 3.18 in. | 58 mm |

| Threads & Feeds | ||

| Threads, Number | 4–56 tpi, 36 | 0.5–7 mm, 17 |

| Modular Threads, Number | 0.019–0.275 in., 17 | 0.5–7 mm, 17 |

| Diametral Pitch Threads | 0.157–2.20 in., 36 | 4–56 mm, 36 |

| Longitudinal Feeds | 0.002–0.032 in./rev | 0.05–0.82 mm/rev |

| Cross Feeds | 0.0001–0.0094 in./rev | 0.02–0.4 mm/rev |

| Leadscrew Pitch, Diameter | 1.37 in., 35 mm | 1.37 in., 35 mm |

| Carriage | ||

| Cross Slide Travel | 10.8 in. | 275 mm |

| Compound Travel | 4.92 in. | 125 mm |

| Compound Width | 5 in. | 127 mm |

| Bed | ||

| Bed Length | 134 in. | 3415 mm |

| Bed Width | 11.8 in. | 300 mm |

| Tailstock | ||

| Quill Diameter | 2.68 in. | 68 mm |

| Quill Travel | 5.9 in. | 150 mm |

| Quill Center Taper | MT #4 | MT #4 |

| General | ||

| Spindle Motor | 7.5 HP | 5.625 Kw |

| Voltage | 220V/440V | 230V/460V |

| Phase | 3 Phase | 3 Phase |

| Power Consumption (220V) | 8 KVA/25 amps | 8 KVA/25 amps |

| Power Consumption (440V) | 8 KVA/12.5 amps | 8 KVA/12.5 amps |

| Approximate Weight | 4,894.26 lbs. | 2,220 Kg |

| Dimensions (L × W × H) | 11.22 × 2.66 × 4 ft. | 3.42 × 0.81 × 2.22 m |

Call for Price

This model is designed with 3.18” spindle hole which is unique for 18” swing lathes. Due to its one piece casting machine base, it can support heavier cutting on large diameter materials. The large through hole allows most 3” diameter oil pipes to be machined.

| Specification | Inch | Metric |

|---|---|---|

| Capacity | ||

| Swing Over Bed | 18 in. | 457 mm |

| Swing Over Cross Slide | 10.2 in. | 259.08 mm |

| Swing Over Gap | 27.17 in. | 690 mm |

| Gap Width (In Front Of Faceplate) | 11.81 in. | 300 mm |

| Distance Between Centers | 86.6 in. | 2200 mm |

| Headstock | ||

| Spindle Speed | 40–2,000 rpm | 40–2,000 rpm |

| Spindle Nose | D1‑8 camlock | D1‑8 camlock |

| Spindle Bore | 3.18 in. | 58 mm |

| Threads & Feeds | ||

| Threads, Number | 4–56 tpi, 36 | 0.5–7 mm, 17 |

| Modular Threads, Number | 0.019–0.275 in., 17 | 0.5–7 mm, 17 |

| Diametral Pitch Threads | 0.157–2.20 in., 36 | 4–56 mm, 36 |

| Longitudinal Feeds | 0.002–0.032 in./rev | 0.05–0.82 mm/rev |

| Cross Feeds | 0.0001–0.0094 in./rev | 0.02–0.4 mm/rev |

| Leadscrew Pitch, Diameter | 1.37 in., 35 mm | 1.37 in., 35 mm |

| Carriage | ||

| Cross Slide Travel | 10.8 in. | 275 mm |

| Compound Travel | 4.92 in. | 125 mm |

| Compound Width | 5 in. | 127 mm |

| Bed | ||

| Bed Length | 134 in. | 3415 mm |

| Bed Width | 11.8 in. | 300 mm |

| Tailstock | ||

| Quill Diameter | 2.68 in. | 68 mm |

| Quill Travel | 5.9 in. | 150 mm |

| Quill Center Taper | MT #4 | MT #4 |

| General | ||

| Spindle Motor | 7.5 HP | 5.625 Kw |

| Voltage | 220V/440V | 230V/460V |

| Phase | 3 Phase | 3 Phase |

| Power Consumption (220V) | 8 KVA/25 amps | 8 KVA/25 amps |

| Power Consumption (440V) | 8 KVA/12.5 amps | 8 KVA/12.5 amps |

| Approximate Weight | 4,894.26 lbs. | 2,220 Kg |

| Dimensions (L × W × H) | 11.22 × 2.66 × 4 ft. | 3.42 × 0.81 × 2.22 m |

Operation Manual and Parts List

Click Here to Open!

Click Here to Open!

Call for Price

We have FREE shipping on all products. This product is too large to be unloaded with a lift gate. Because of this, it will take equipment to unload it. You will need your own equipment to unload it yourself or you can rent equipment to unload it or you may hire a rigging company to unload it for you. If you are unsure how to do this, please give us a call at (888) 884-9064 or email us at support@machineauthority.com.

Make sure to read our Authority Rigging Assistant Service tab to see the service we offer to help with this.

Thanks!

Do you need help unloading your new machine? Don't use your valuable time researching and calling local rigging companies. Have us do it for you!

The Authority Rigging Assistant is our service available for any order over 9900$. We will find several local rigging companies for you and get rough quotes from them on your behalf. Then you can choose the best one and work with them on the final details. We also provide recommendations as to how to get rid of your old machinery if you need it.

Have professional machinery movers with liability coverage take the worry out of your delivery day. Make sure to ask us about getting an Authority Rigging Assistant!