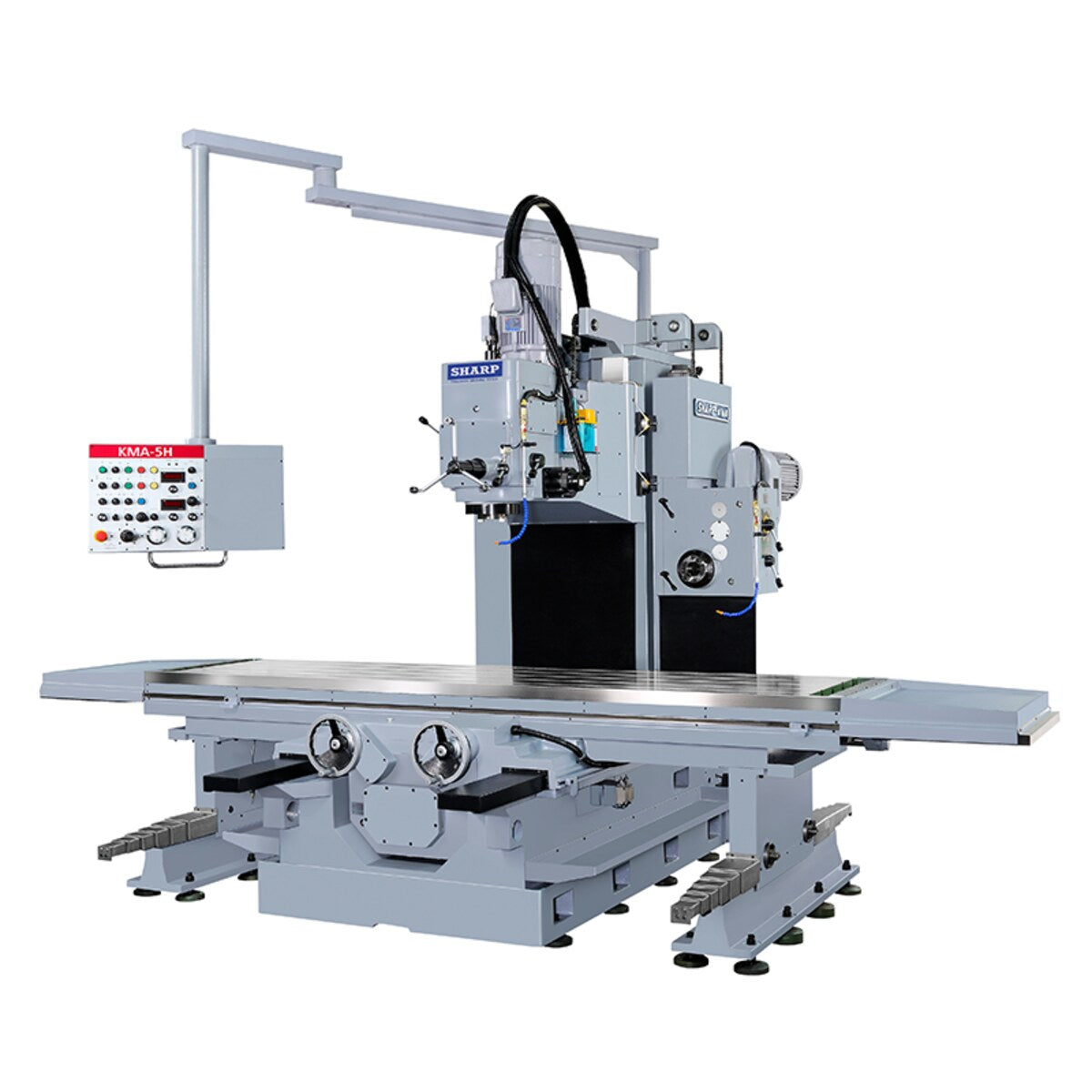

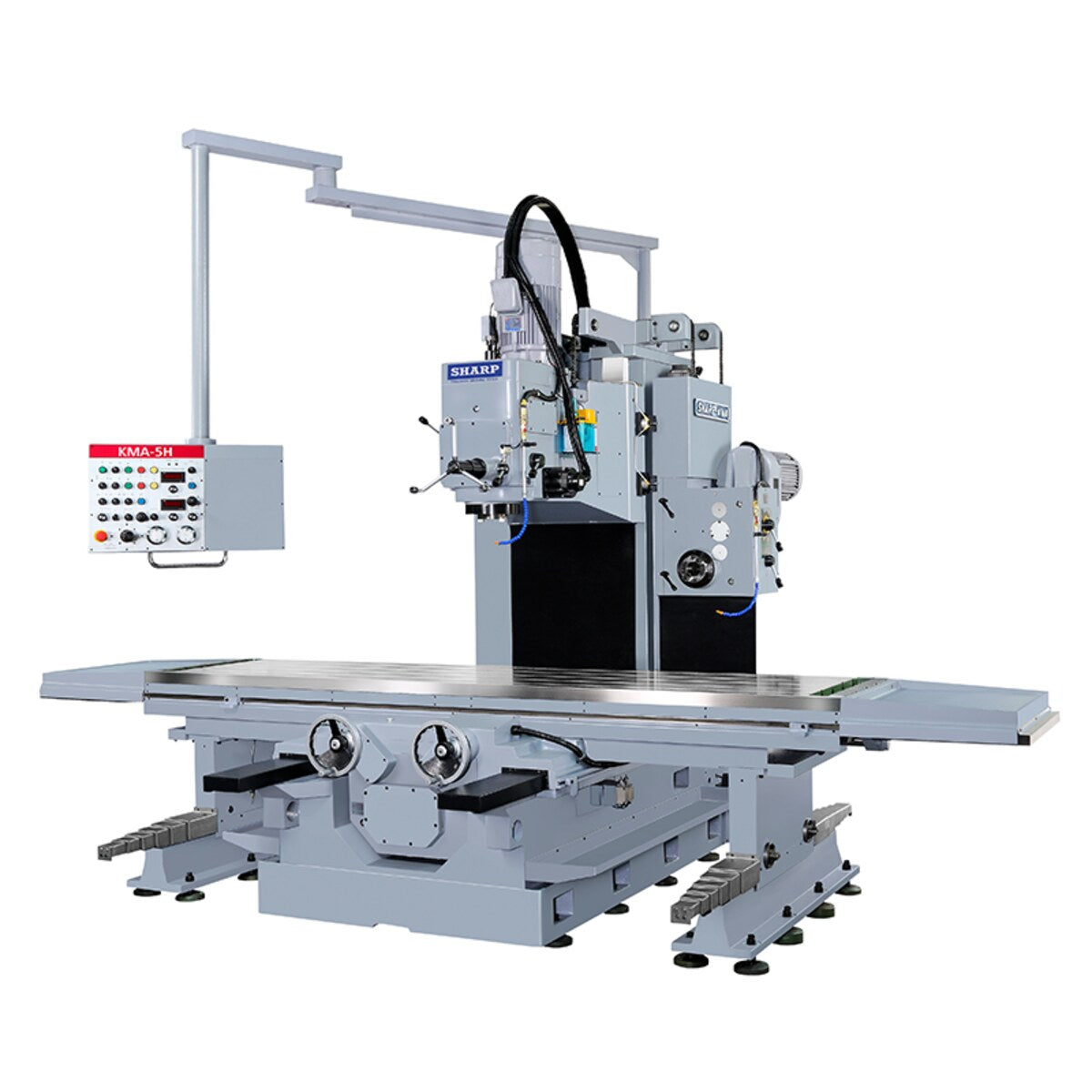

Sharp Industries 30" x 106" Bed Type Vertical/Horizontal Milling Machine KMA-5H

There is a 6% surcharge on all Sharp products due to tariffs.

Feel free to call in to ensure product availability and lead times.

There is a 6% surcharge on all Sharp products due to tariffs.

Feel free to call in to ensure product availability and lead times.